Choices - Western Lumber and the Environment

Every building product we use today comes from natural resources. Many of these resources are being depleted at an accelerating rate. The large consumption of energy – mostly from non-sustainable sources – is also increasing the environmental costs of extracting and producing many of these materials.

The world is becoming more conscious of how human actions can impact the health of this planet. Today, societies around the globe are asking important questions about the environmental costs and benefits of all the things that are part of everyday life. Evaluating the environmental impact of product choices is increasingly important to help address sustainability issues.

For building materials, too often comparisons of the “green” benefits of certain products are incomplete and do not reflect the responsible choice for the environment. Before making any product selections, we should have all the information on how each material ultimately affects the world we wish to perpetuate.

Once all the facts are reviewed, there is only one clear environmental choice in building materials: wood.

WHY WOOD?

Wood is the oldest material used by humans for construction after stone. Assessing the environmental impact of today’s building materials (steel, wood concrete, masonry, plastic, composites and glass) requires a look at the full life of the product, from its extraction to manufacturing, through its use in service to disposal. At every step, each of these products can impact our environment.

Wood is the oldest material used by humans for construction after stone. Assessing the environmental impact of today’s building materials (steel, wood concrete, masonry, plastic, composites and glass) requires a look at the full life of the product, from its extraction to manufacturing, through its use in service to disposal. At every step, each of these products can impact our environment.

Figure used by permission Washington Forest protection Agency www.wfpa.org

Out of all of these materials, wood emerges as the most environmentally responsible choice available today.

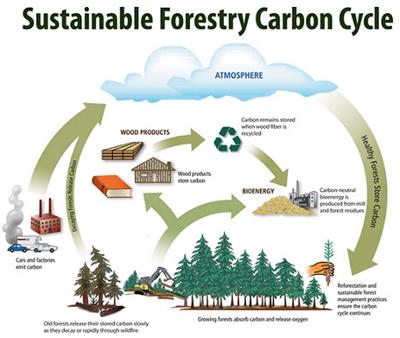

Wood grows naturally and is renewable. Wood comes from trees, which absorb carbon dioxide and releases oxygen. For example, a sustainable forest system produces 1.2 tons of oxygen and absorbs 1.83 tons of carbon dioxide for every ton of wood fiber. Another way of viewing this is a typical new 2,062 square foot wood-frame house could contain 21,000 lb of wood (absolute dry). On average, wood contains about 50 percent carbon by weight. Therefore, this home would store 10,500 pounds of carbon, equivalent to sequestering 38,500 pounds of CO2 or the rough equivalent of removing 10 cars off the road for one year.

Wood is converted into thousands of products, from lumber, panels, and paper products to shoe polish, liquid soaps and cologne.

Wood’s natural attributes make it uniquely suited to both the performance and environmental demands for modern building materials. Despite its complex chemical nature, wood has excellent properties which lend themselves to human use. It is readily and economically available, easily machined, can be fabricated into an infinite variety of sizes and shapes, and it is exceptionally strong relative to its weight.

Wood is a good heat and electrical insulator, and it is renewable and biodegradable, which has become an increasingly important attribute for building material choices. In building, wood has a high ratio of strength to weight and boasts a long history of durability and performance in construction. Wood resists oxidation, acids and other corrosive agents and easily accepts preservatives, fire retardants and a variety of finishes.

In building, wood has a high ratio of strength to weight and boasts a long history of durability and performance in construction. It features superior insulating properties against heat, sound and electricity. Wood resists oxidation, acids and other corrosive agents and easily accepts preservatives, fire retardants and a variety of finishes.

CARBON SEQUESTRATION

Carbon sequestration is defined as the process of “carbon capture” of atmospheric carbon dioxide (CO2). Trees, grasses, and other plants can absorb CO2 from the atmosphere through photosynthesis. The CO2 is stored as carbon in the trunks, branches, foliage, roots, and soil. Sustainable forest practices can increase the ability of forests to sequester more carbon and help offset sources of atmospheric CO2 resulting from deforestation, forest fires, and fossil fuel emissions. Planting new trees and improving forest health through thinning and prescribed burning are some of the ways to increase forest carbon in the long term. The wood products used in homes and buildings store carbon during their life span, but also release far less CO2 during their manufacturing compared to equivalent use non-wood fossil intensive products (steel and concrete).

SUSTAINABLE WESTERN LUMBER

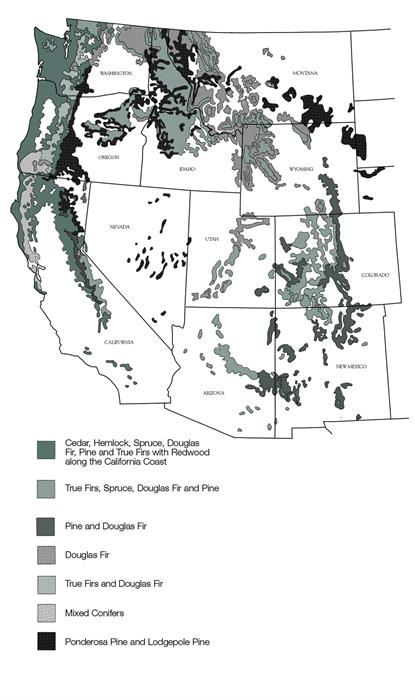

The West features a rich diversity of timber, with 231 million acres of forestland throughout the region. Of that acreage, just 126 million acres is available for commercial timber production and the remaining is reserved for wilderness, watershed protection, wildlife, parks and other non-commercial activities.

More than half of this timberland is owned by the federal government, which is managed by the U.S. Forest Service and Bureau of Land Management. The forest industry and other private landholders own 34 percent of this land and state and other public agencies account for the remaining 10 percent.

Recognizing the need for proper management and protection of the West’s forest resources, timber companies and public agencies developed the first of the western forestland management laws in the early 1940s. The Oregon Forest Conservation Act of 1941 provided the framework for laws such as the Oregon Forest Practices Act, adopted in 1971. Other states, including Washington, California and Idaho, have adopted similar forest practices laws.

The evolution of these laws and improvements in forest management practices in the West has provided the foundation for some of the toughest, most progressive forest laws in the world. Ongoing private and publicly funded research has led to improvements in stream and watershed protection, fish and wildlife habitat, and other forest values important to society. The forest management practices used in the West today are designed to improve the whole forest ecosystem rather than for specific values.

There are a host of wood species available to meet any construction or aesthetic need. In the West alone, there are more than 15 commercially available species produced and sold by mills today.

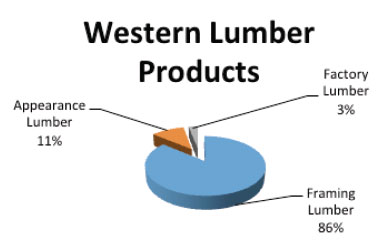

These Western species are cut into a variety of products, from framing lumber for building structures to common boards for shelving, paneling and material handling to factory grade that are further sawn into wood components for doors, windows and other products.

FOREST HARVESTING AND RENEWABILITY

FOREST HARVESTING AND RENEWABILITY

There is a popular misconception that America’s forests are disappearing and that we are running out of trees. The facts, however, show just the opposite.

Forest growth in the U.S. has exceeded harvest continually since the 1940s. According to the Forest Service, the U.S. forest inventory has actually increased by 39 percent since 1952.

One-third of the U.S. is forested or 751 million acres with 56 percent privately owned. Privately owned forest supply 91 percent of the wood harvested in the U.S. State and tribal forests supply approximately 6 percent, and federal forests supply only 2 percent of the wood used by the forest products industry. In 2012, the U.S. Forest Service reported that 3.2 million trees planted per day in the U.S.

The forest products industry does more than just plant and harvest trees. As foresters, wood products companies follow rigorous standards and forestry practices to protect the trees, soil, air, water and wildlife.

SUSTAINABILITY AND CERTIFICATION

SUSTAINABILITY AND CERTIFICATION

Forests play an important role in the environment, a fact long recognized by wood products producers. As users seek to know more about the sustainability of the building materials they use, more information is being developed to help make buying decisions.

Forest certification is one way to demonstrate the sustainability of wood products. Much of the Western lumber made today is covered by certified sustainable standards that are audited by independent third parties recognized worldwide.

The Sustainable Forestry Initiative (SFI) and the Forest Stewardship Council (FSC) programs both certify lands in the United States and Canada. Studies have shown buyers and consumers appreciate the value of forest certification to help them choose forest products from responsible sources. About 58% of the forests in North America are certified. SFI has certified an estimated 250 million acres of timberland in North America, of which 65 million acres are in the U.S. While the FSC certification program, which operates globally, has certified 173 million acres in the U.S. and Canada, with 35 million acres in the U.S. Both these standards have criteria that include process and performance-based indicators that address environmental, forestry, social, and economic issues.

Both these standards have criteria that include process and performance-based indicators that address environmental, forestry, social, and economic issues.

Wood products that meet the standards set by the certifying organization are typically marked on the product itself, the paper wrap used in shipping or in documentation that accompanies the product.

GREEN BUILDING

Forest certification is only one way of documenting the sustainability and environmental benefits of wood products. A growing number of communities are also considering green building standards that provide incentives or recognition for using materials or following practices that are friendly and safe for the environment.

Wood is the perfect green building material because it is renewable, stores carbon that reduces greenhouse gases, and is energy efficient. Several green building ratings systems are in place today such as Green Globes® through the Green Building Initiative, The National Green Building Standard, and LEED™ (Leadership in Energy and Environmental Design).

Comparing the environmental impacts and benefits of different materials can be difficult, given the wide variety of way these products are extracted, produced and used.

Scientists, government officials and others are turning to life cycle assessment (LCA) to provide a “cradle to grave” environmental profile of building materials.

The Consortium for Research on Renewable Industrial Materials (CORRIM) has performed extensive LCA of several building materials produced in the U.S. CORRIMs results show wood is superior in its environmental performance to concrete and steel. Comparing houses constructed of these three different materials and identified numerous advantages for wood-frame construction. The CORRIM results show that wood components and assemblies outperformed steel in terms of global warming potential, air and water emissions, and solid waste and surpassed concrete in all but water emissions impact categories. In some cases, up to 5 tons CO2 equivalent is displaced when comparing a concrete frame to a wood-framed house. In general, substituting fossil intensive building materials for renewable wood products displaces 2.1 pounds of CO2 for every 1 pound of wood used.

The CORRIM results show that wood components and assemblies outperformed steel in terms of global warming potential, air and water emissions, and solid waste and surpassed concrete in all but water emissions impact categories. In some cases, up to 5 tons CO2 equivalent is displaced when comparing a concrete frame to a wood-framed house. In general, substituting fossil intensive building materials for renewable wood products displaces 2.1 pounds of CO2 for every 1 pound of wood used.

New tools are available to the public to compare building materials in a structure using LCA science. The Athena Sustainable Materials Institute (ASMI) offers the Impact Estimator (IE) for Buildings. This whole-building tool can be used to explore the environmental footprint of different material choices. Architects, engineers, and others can easily compare the environmental footprint of new buildings and renovations for all building types in the U.S. and Canada.

As more green building standards emerge, science-based analysis such as LCA offers the most impartial and comprehensive way of determining the environmental impacts of materials. Although LCAs provide a scientific foundation for assessing the environmental performance of products, they are not well suited to communicate results that are meaningful to architects, builders, consumers, or businesses that are not familiar with LCA.

ECOLABELING

Transparent and scientifically sound environmental labeling of products is vital for a sustainable future. Environmental Product Declarations (EPDs) are standardized summaries of the environmental impacts linked to a product or process. Based on the definition, EPDs are EcoLables used as a way to improve the quality, credibility, and transparency of environmental impact information available to consumers and businesses. EPDs could provide a way to communicate the environmental benefits of wood to consumer or incorporated in purchasing preference programs and green building rating systems.

EPDs are based on LCA results and can be used to compare products on an equal basis. LCA results and the EPD go through a rigorous third party verification and certification process. The North American wood products industry has published several EPDs on wood products including softwood lumber

(http://www.awc.org/greenbuilding/epd).

RESPONSIBLE CHOICES

It all comes back to choices. If we are to join the growing number of responsible people who advocate the sustainable and wise use of our natural resources, we must measure our choices between one building material and another. We must look at all aspects of each material, from extracting through manufacturing to use, recycling or final disposal. This holistic vision allows us to consider the variety of impacts such actions can have on our planet.

By nearly any measure, wood offers the best choice among building materials for most uses. It is strong, light, durable and safe to handle. It uses less energy over its lifetime, generates little pollution and is biodegradable for disposal. It is naturally renewable and there are ways to assure that the wood we use is being produced sustainably and responsibly.

We have the ability to take anything we want from this earth. But we also have the responsibility to take it wisely and give back what we can. We all have choices. In building materials, there is only one clear choice: wood.

SOURCES

American Forest and Paper Association,

www.afandpa.org

American Wood Council, www.awc.org

Athena Sustainable materials Institute,

www.athenasmi.org/

Consortium for Research on Renewable Industrial Materials, www.corrim.org

Dovetail Partners, Inc., www.dovetailinc.org

Forest Stewardship Council (FSC), www.us.fsc.org

Oregon Forest Practices Act.

www.oregon.gov/ODF/Working/Pages/FPA.aspx

reThink Wood, www.rethinkwood.com

Sustainable Forestry Initiative (SFI)

http://www.sfiprogram.org

Washington Forest Products Association,

www.wfpa.org